High Capacity Wood Sawdust Pellet Mill

Basic Info

Model No.: XBG568

Product Description

High Capacity Wood Sawdust Pellet Mill

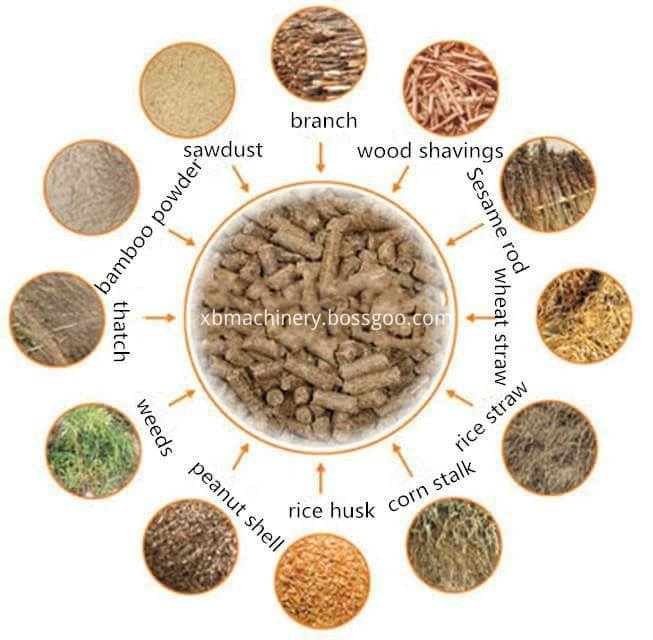

Q: What kind of materials can be using for pellet making?

A: Sawdust, EFB, Rice husk, straw, agriculture waste, grass, and other different kind of biomass materials

Q: Which moisture content is suitable for pellet making?

A: Most suitable moisture content is 10-15%.

Q: Which size can be feeding into pellet machine?

A: normally need the raw materials size smaller than the diameter of the output pellets diameter.

Q: What's your warranty time of the machine?

A: The roller husk and the ring die

Q: What's the wearing parts for the pellet machine?

A: 1 year, except the wearing parts.

Q: What 's the density of the output pellets

A: pellets density is 1.0-1.4g/cm3

Introduction:

Biomass Pellet Granulator Machine

1 The machine adopted the bevel gear transmission, compact structure, high transmission efficiency low electricity consumption;

2 The right end of the overload protection device structure;

3 To ensure that the small straw material fast into pellet room, specially designed with a forced feed mechanism;

4 The auger of forced feed structure adopted special uniform materials to feed uniformity;

5 To those fluffy, bulk density light straw adopted twisted dragon blade, screw combination structure ensure the straw conveying uniformly;

Working principle:

The raw material is under dried condition, which is compressed, and formed into small eraser-sized bits, the final pellets is clean, pleasant and smooth, and its density is more than 1.0 g/m3

Normally we have to stop the pellet machine to fill the grease into rollers manually when the machine works for every 2 hours, it is inconvenient for making Pellets constantly. So we have designed the auto lubrication system for all bearing of rollers to improve efficiency without stopping the machine

Advantages of biomass granulator:

Model CE Approved Flat Die Biomass Wood Granulator

Model Capacity

(kg/h) Motor

(kw) Pellet size

(mm) Applicable materials moisture Dimensions

(mm) Weight

(kg/set)

XBF-200 80~120 7.5 6,8,10 14%~20% 1150*530*800 320

XBF-250 150~200 15 14%~20% 1200*600*1300 350

XBF-300 200~300 22 14%~20% 1300*600*1300 560

XBF-350 350~450 30 14%~20% 1300*700*1400 880

XBF-450 400~600 45 14%~20% 1800*1000*1650 1300

1300*560*1100

Pre-sales service:

Receive customer consultation, determine the scale of operation according to customer demand, and provide plant construction plan;

Provide customers with project design and process flow design, which is suitable for the formulation of the purchase plan of your machine equipment, and provide customers with relevant technical documents in time.

According to your special needs, design products, train technical operators for you to carry out preliminary design and construction design.

In-service:

We send technicians to the site to guide the installation, commissioning and training of operators

24-hour telephone service throughout the day, holiday service as usual.

After-sales service commitment:

Telephone support means that the customer asks for technical support and help from us by phone or fax when they encounter difficulties in using the equipment or when the equipment is abnormal.

After confirming the customer's service request, we will arrange technicians to help the demander locate the fault within the specified time (i.e. response time) by telephone, and propose solutions, so as to finally guide the customer to troubleshoot the equipment fault.

Field support and failure recovery commitment

On-site support means that the customer asks us for technical support and help by phone or fax when they encounter difficulties in using the equipment or when the equipment is abnormal.

After confirming the customer's service request, if the fault cannot be diagnosed and solved by telephone, we will send technicians to the site to deal with it immediately and finally solve it.

Our products offer "three packages".

One year warranty, lifetime maintenance;

24 hours receiving technical consultation, providing technical diagnosis to customers;

The maintenance personnel shall be in place immediately after receiving the fault notice to troubleshoot the fault;

Assist user system upgrade, equipment and mold update.

Company show:

Shandong qufu xingbang heavy industry equipment co., LTD will build a science and technology leading enterprise integrating research and development, manufacturing and installation, and international trade.

Main development and production of products are building materials equipment: automatic glass magnesium fire board production line, large multi-function wall board exterior wall insulation board production line, fire door core board production line of environmental protection and new energy straw making machine, fully automatic quadrilateral cutting saws;

Woodworking machinery, automatic cover machine, labeling machine, automatic finishing machine, UV light solid machine, hot pressing machine, vacuum molding machine, cold press machine, universal coating machine, and other products, the above products have passed the relevant state departments of technical appraisal and recognition, has enjoyed good reputation in the market, obtained the customer consistent high praise.

The products produced by the company are sold to all over the country and some surrounding countries and have achieved high economic and social benefits.

Product Categories

Building Material Making Machinery

Compound Ventilation Tube Sheet Metal Production Line

Automatic Four Edge Cutting Saw

Large Fireproof Door Core Board Production Line

Fully Automatic New Compound Straw Tile Production Line

Fire Prevention Board Machine Straw Door Equipment

Fire Prevention Board Production Line

Polyurethane Low Pressure Foaming Machine

Polyurethane High Pressure Foaming Machine

Glass Magnesium Fire Prevention Board Plate Automatic Production Line

Glass Magnesium Fire Board Decorating Plate Production Line

Plastic Extrusion And Recovery Equipment

Plastic Extruder Machine

Plastic Pelletizing Recycling Machine

Sheet Plate Board Extrusion Line

Plastic Washing Recycling Machine

PVC WPC Profile Extrusion Line

Plastic Pipe Extrusion Line

Plastic Crusher & Granulator

Plastic Shredder

Plastic Auxiliary Machine

Woodworking Machinery

Wallboard Decorative Machine

Door Decorative Machine

Cabinet Decorative Machine

Floor Decroative Machine

Moulding Line Decroative Machine

Veneer Machine

Indoor Decroative Machine

Woodworking Wrapping Machine

Sawdust Granulator /Wood Pellet Granulator

Wood Door Vacuum Laminating Machine

Environmental Protection Equipment

Waste Gas Treatment Equipment.

Dust Removal Equipment

Plastic Injection Molding Machine

Plastic Injection Molding Machine

Plastic Blow Molding Machine

Product Categories : Woodworking Machinery > Biomass Granulator